We provide systems for complete process lines starting from raw material handling up to packing stations. We provide best in class service support for all types of Process Control Equipments, Valves and Components. We support Erection, Installation, Commissioning & Start-Up Services.

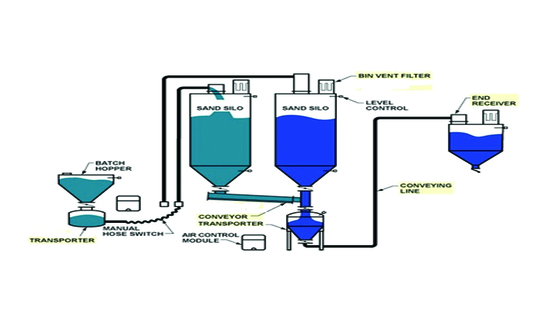

Bulk material in the form of granules or powders is transported through a pipe by using the flow of air or other gas.

Allows secure storage of your powders and bulk materials. Compact design allows easy assembly and disassembly.

Our bag dumping station allows for efficient and effective emptying of bags of bulk solids, either powders and granules, while mitigating loss of product through dusting.

The process of transferring large quantities of bulk materials from specialised transport vehicles, called bulkers or bulk carriers, into storage silos, bins, or processing equipment.

A batching and weighing system measures the weight of ingredients before mixing or processing them to ensure the quality and consistency of the final product.

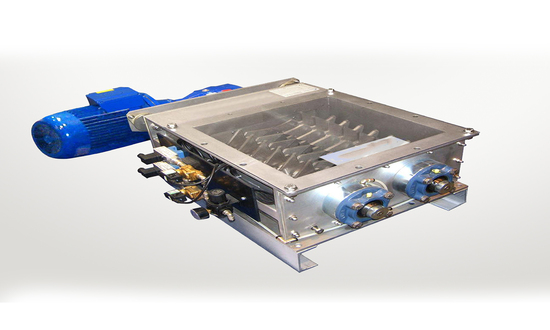

of industrial mixing equipment used for blending dry powders, granules, and other solid materials.

Mechanical device used to separate and classify bulk materials based on their size, shape, density, or other characteristics.

grinding mill used in various industries for particle size reduction and classification of materials.

process of transferring bulk materials from large flexible containers, commonly known as big bags or FIBCs (Flexible Intermediate Bulk Containers), into downstream processing equipment or storage vessels.

Controls the flow of granular or powdered materials between two chambers with different pressure levels.

Conveying systems used to transport bulk materials horizontally, vertically, or at an incline

These systems are essential in various industries such as woodworking, metalworking, pharmaceuticals, food processing, mining, and manufacturing, where dust generation is a common byproduct of production operations.

used to accurately dispense precise quantities of liquids, powders, granules, or other substances into a process or application.

Equipment used in various industries to control airborne dust and particulate matter generated during material handling and processing operations.

Controls the flow, pressure, temperature, or level of fluids (liquids, gases, or slurries) within a system.

Promotes the flow of bulk materials from storage bins, silos, hoppers, or bunkers.

Used in various industries for separating ferrous contaminants from bulk materials in processing lines.

Collects representative samples of powdered materials for analysis, testing, quality control, or process monitoring purposes.

Mechanical devices used to connect two shafts or components while allowing for relative motion, misalignment, or vibration isolation between them.

Reduces oversized or agglomerated materials into smaller, more manageable pieces.

Enhancing the lifetime of your valves to another 3-4 years of span.

Servicing of valves irrespective of the Brand / Make.

Well trained and well equipped team with latest tools & tackles.

Service offered with Testing & Calibration, to assure integrity & operation of the Valve.